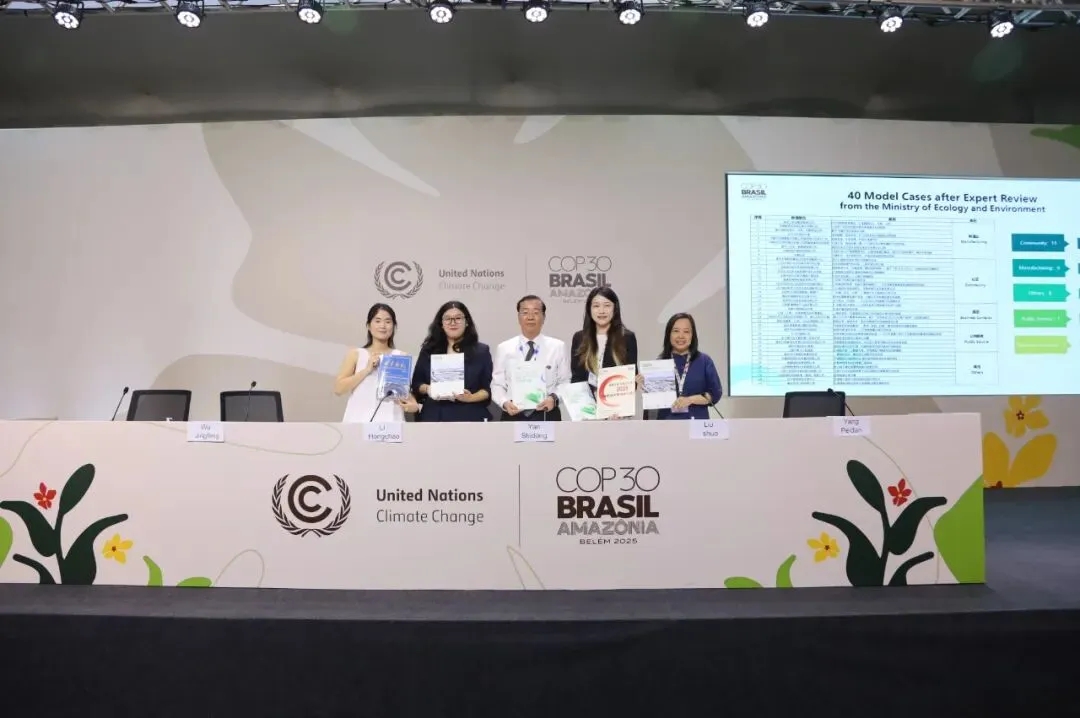

On November 17th (local time), at the press center of the 30th Conference of the Parties to the United Nations Framework Convention on Climate Change (COP30) held in Belém, Brazil, the Publicity and Education Center of the Ministry of Ecology and Environment, together with the China Champions for Climate Action, held the launch event of 2025 Beautiful China · Green Space Users Case Collection (hereinafter referred to as the "Case Collection"). Among the 40 selected cases, Yangtze River Pharmaceutical Group (YRPG) was successfully included with its case titled “Building a Zero-Waste Benchmark in the Pharmaceutical Industry.”

Uphold the concept of sustainable development and establish a "Zero-Waste" benchmark in the pharmaceutical industry

In October 2023, YRPG launched the construction of Jiangsu Province’s first "Zero-Waste Group" in the pharmaceutical industry. By adopting measures such as source reduction and recycling, YRPG has enhanced the resource utilization efficiency of solid waste and mitigated environmental risks. In 2025, the group innovatively proposed the development of "Zero-Waste Workshops" within its factories, introducing evaluations based on the generation, recovery and utilization rates of hazardous waste in each workshop to further implement the "Zero-Waste Group" initiative with greater precision and depth. To date, 100% of YRPG’s operational factories have passed cleaner production audits. The cumulative reduction and resource utilization of industrial solid waste has reached approximately 2,173 tons, generating economic benefits of around RMB 12.3366 million, with five of its factories awarded the local "Zero-Waste Factory" title.

Material reduction for packaging

To simultaneously meet requirements related to Good Manufacturing Practices (GMP) and Environmental, Social, and Governance (ESG), YRPG has formulated the Regulations on the Management of Pharmaceutical Packaging Materials of YRPG (hereinafter referred to as the "Regulations"). The Regulations define full-process control requirements covering packaging material quality and acceptance, systematically advancing packaging material reduction. Examples include:

Factories directly print drug insert information on packaging boxes to reduce the use of separate inserts—for instance, the annual paper consumption for doxofylline injection has been reduced by 10.84 tons;Factories have reduced the specifications of blister packaging for Lanqin Oral Liquid, cutting down on plastic packaging usage by 4.47 tons per year.

Recycling of organic solvents

As a key reaction medium in pharmaceutical production, organic solvents typically consume several times the amount of the final product per batch. To reduce solvent usage, YRPG has implemented effective measures from the perspective of production process optimization. For instance, during the manufacturing of specific drugs, the group’s factories adopt distillation, concentration and other methods to recover and reuse chemical solvents. In 2024 alone, 1,477 tons of solvents were recycled and reused, generating cost savings of RMB 10.5 million.

Paperless office

To streamline the daily management processes of laboratories and advance the transition to a paperless office, in accordance with the unified deployment of YRPG, all its factories have adopted the Electronic Laboratory Notebook (ELN) system. This system enables the digital collection, classification, storage and retrieval of laboratory data, facilitating the centralized management of data. Since the commissioning of the ELN system, a single factory has saved approximately 560,000 sheets of paper annually. By the end of 2024, YRPG had promoted the application of the ELN system to 10 of its factories, achieving paperless operation in laboratories across these facilities.

Industrial chain integration of solid waste

YRPG has comprehensively assessed the current status of solid waste, fully explored the potential for its resource utilization, and actively established cooperative relationships with solid waste disposal entities to gradually improve the comprehensive utilization rate of solid waste. For example, the group has collaborated with activated carbon manufacturers to jointly explore resource utilization pathways, converting waste activated carbon that was previously incinerated into recyclable resources—recovering and reusing 53 tons of waste activated carbon in 2024 alone. Additionally, its factories have entrusted qualified institutions to conduct hazardous characteristic identification on sludge generated from sewage treatment stations. Confirming the sludge as general industrial solid waste, and following filing with ecological and environmental authorities, YRPG has partnered with disposal units to utilize drying technology, repurposing the sludge as raw material for brick-making. A total of 87.1 tons of sludge were comprehensively utilized in 2024.

Meanwhile, YRPG has actively promoted the experience of its outstanding "Zero-Waste Group" practices. On one hand, the group participated in compiling the industry standard T/UNP 724—2025 Guidelines for the Construction of Zero-Waste Factories in Pharmaceutical Enterprises, leading the top-level design of "Zero-Waste Factories" in the pharmaceutical industry. On the other hand, relying on platforms such as the "2025 Eco-Forum Global Guiyang ESG Cases" and "Outstanding ESG Practices in Chinese Enterprises' Internationalization", YRPG has shared its exemplary approaches to support the "zero-waste transformation" of the pharmaceutical industry.